Complete vehicle homologation arises not only from the mandatory registration of individual components, but also from the need to coordinate the various component certifications as part of the overall homologation process. For the supplier industry, this means that in many cases the specifications for component approval are made by the OEM.

The management of this issue is also made complex by the fact that CCC certification of vehicles and automotive parts is not mandatory for all components in the automotive sector, some even cannot be certified, and some components are not subject to mandatory certification but still must prove conformity with Chinese regulations. This is not only confusing for the manufacturers, but also can be for Chinese customs authorities, which is why it is not uncommon for shipments to be detained or even rejected.

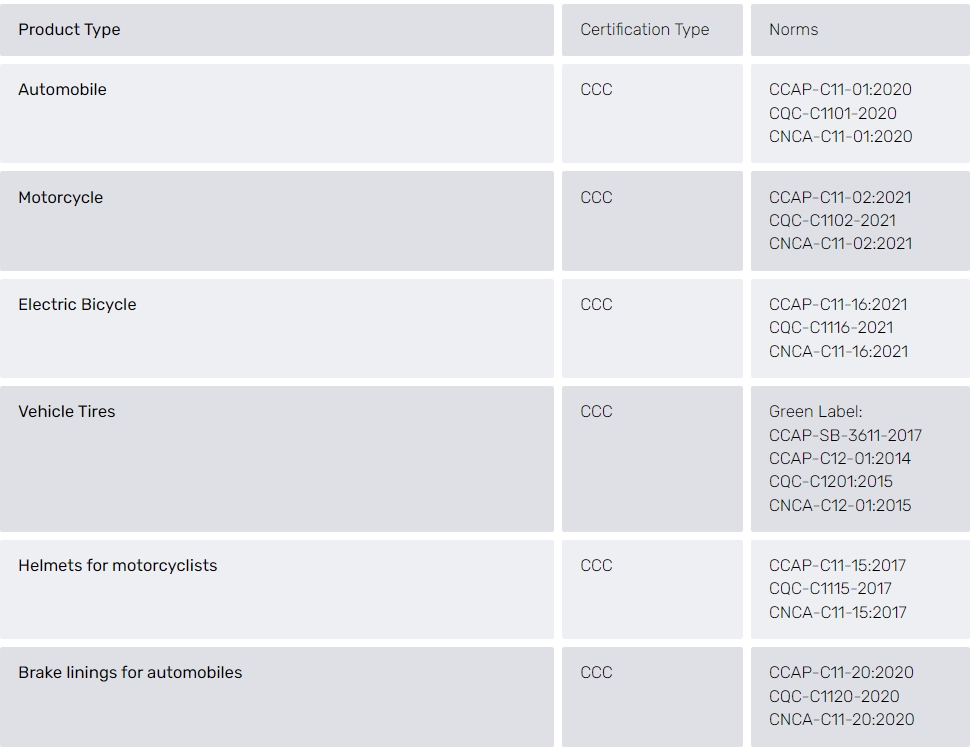

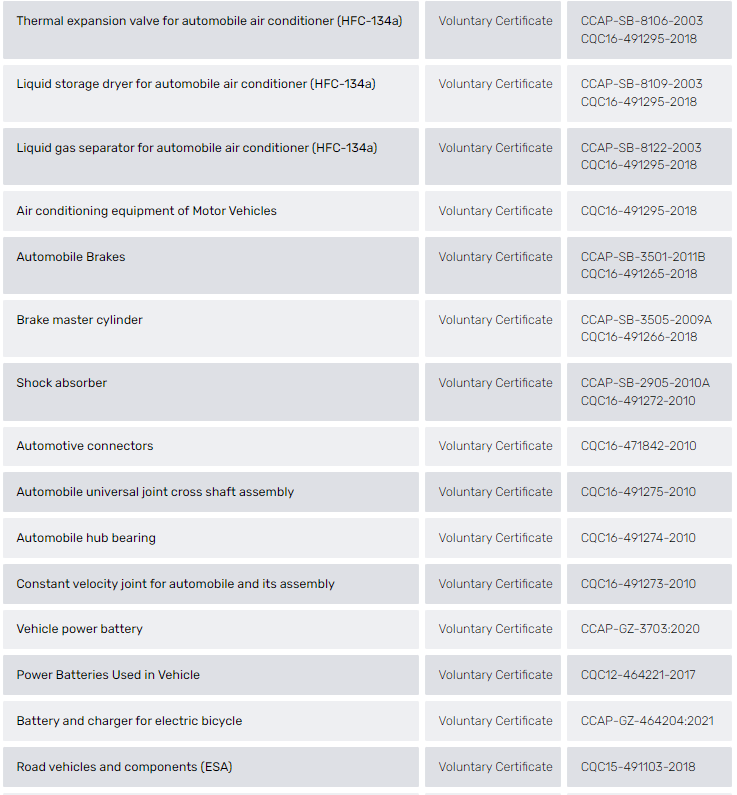

Different CCC certification types for automotive components:

CCC Certifcation:

The standard CCC certification is the official regulatory approval procedure according to the Chinese Implementation Rules of the CNCA (Certification and Accreditation Administration of the People’s Republic of China). As part of this procedure, products must undergo specific product tests in each case and production facilities must conduct a factory audit. The requirement for CCC approval applies to numerous automotive components such as safety glass, tires, child seats and more.

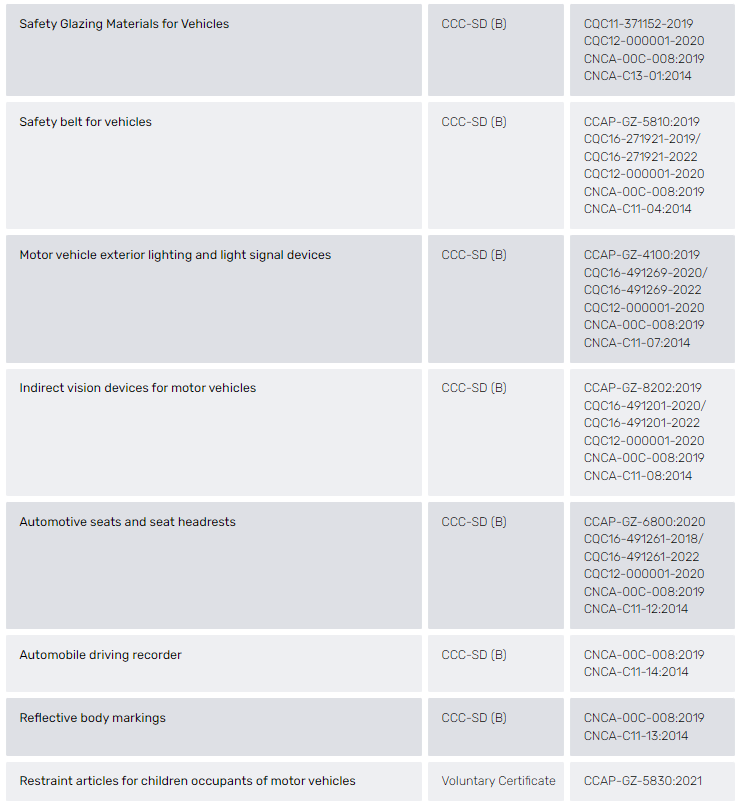

CCC Self- Declaration

For many automotive components such as seats or exterior lights, CCC Self-Declaration is mandatory. The manufacturer must submit a declaration that it complies with Chinese safety standards on an ongoing basis and conducts regular product tests. The authority reserves the right to check this at any time. The easiest way to prove ongoing product conformity is with annual voluntary certification. CCC self-declaration and voluntary CQC/ CCAP certification are often combined.

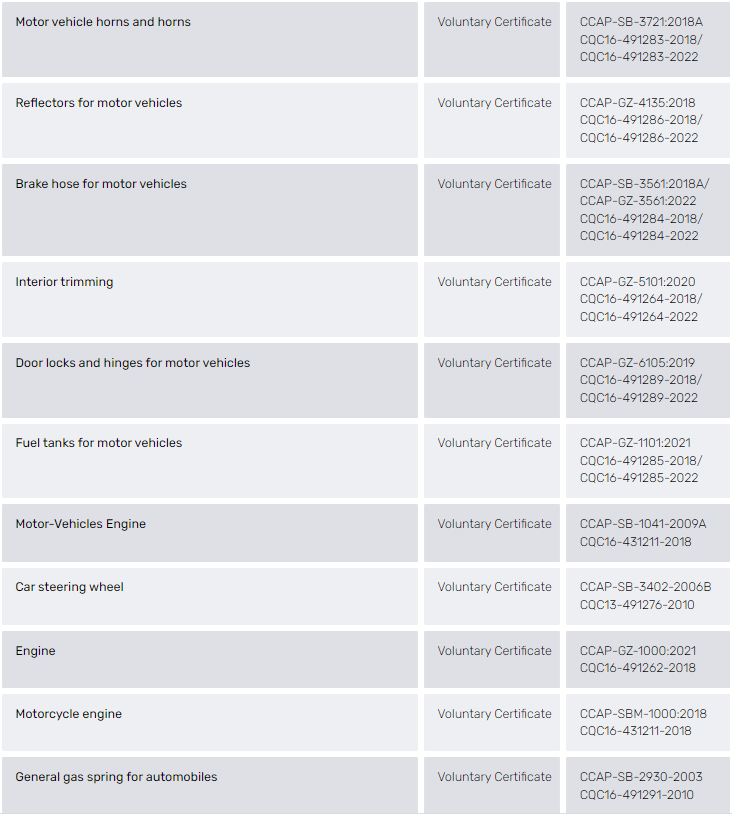

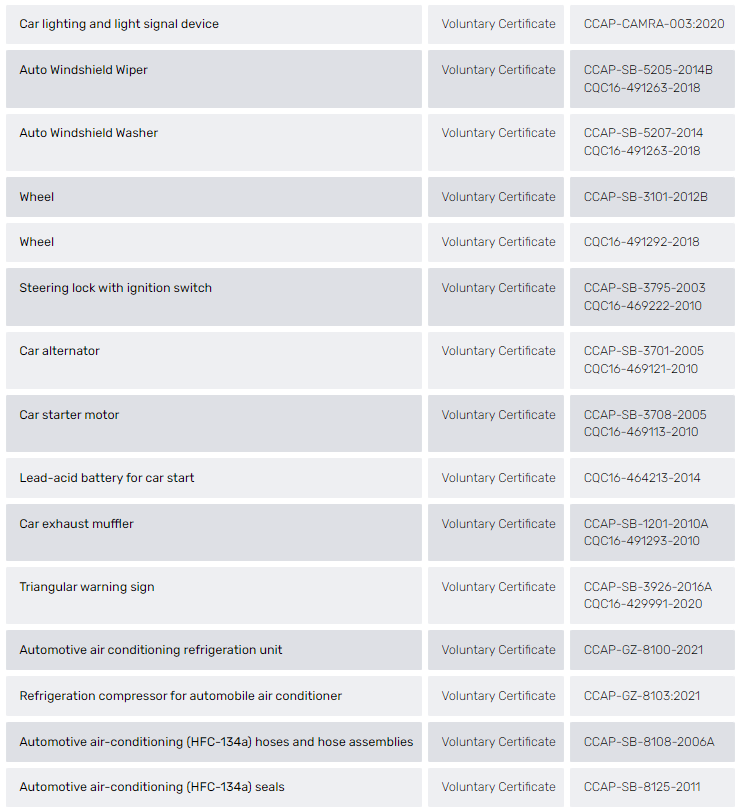

Voluntary CQC and CCAP Certification

Voluntary CQC or CCAP certification can be applied for numerous components. The voluntary certification applies to many components that were CCC mandatory until recently, or for which a CCC Self Declaration is required now. In many cases, a CQC or CCAP voluntary certification is required by the vehicle manufacturer to ensure product conformity.

Complete Vehicle Certification for China

CCC certification for complete vehicles is especially complex

CCC for interior components

Since October 2019, vehicle interior components no longer require a CCC certification in China, as per Announcement No. 44 by the Chinese authority CNCA. However, manufacturers must continue to ensure product conformity with Chinese regulations. For this purpose, voluntary CCAP certification or CQC certification can be useful and provide additional security. In most cases, the voluntary certification is required by the vehicle manufacturers when the vehicle is exported to China.

Questions and problems often occur regarding certification for automotive suppliers when it comes to the exact classification of products in the voluntary certification of interior trim components. To clarify whether an interior component can be voluntarily certified, various criteria must be checked, such as: Size of the component, location in the vehicle and function of the component. Usually, it can only be clearly determined whether a component can be certified after consultation with the Chinese authority.

Once it has been determined that a part can be certified, the unit classification must be determined to see how many applications, tests and certificates will be needed. Components are grouped into different certification units. The unit classification depends on the material(s), material suppliers, thickness, and assembly of the component. Which production site is responsible for the certification process should be thoroughly clarified with the Chinese certification authority. As a rule, the site where the final quality assurance step is taken on the component must be audited. There must be a value-add process prior to quality assurance at this location for it to be considered.

Relevant norms & GB standards for automotive component

According to the CNCA standard, a passenger car is subject to CCC certification as a complete vehicle. Numerous individual components also fall under CCC obligation, while others can only obtain voluntary CQC/ CCAP certification.

The vehicle manufacturer can test certain components as part of his complete vehicle homologation but this means a high time expenditure for changes to the supplier components. In addition, the components may not be marked with the CCC symbol. The certification of the component itself can be regarded as an efficient solution, to avoid problems with Chinese customs.

Overview of the products that are subject to certification or which can be certified in the automotive sector:

Source: MPR China Certification

![[MIC] Officially issued QCVN 134:2024/BTTTT - National technical regulation on specific absorption levels for handheld and body-worn radio devices according to Circular 19/2024/TT-BTTTT of Ministry of Information and Communications](https://cdn0577.cdn4s.com/thumbs/qcvn-134_thumb_150.jpg)

![[Latest] Circular 02/2024/TT-BTTTT regulating the List of potentially unsafe products and goods under the management responsibility of the Ministry of Information and Communications](https://cdn0577.cdn4s.com/thumbs/trang-huy-hieu-the-loai-logo-2_thumb_150.jpg)