EMI interference is a form of electromagnetic wave disturbance that reduces the efficiency of a device and even causes it to stop working. EMI has two manifestations, first through wires, electrical devices are affected, second is through space radiation.

Currently, commonly used household appliances such as mobile phones, automatic control devices, computers, music players, televisions, etc. are certainly affected by electromagnetic interference. The degree of influence varies depending on the level and results of reducing quality or causing information distortion. For example, when a computer is affected by electromagnetic interference in excess of the allowed level, it will lead to a hang or, more seriously, data loss.

Therefore, the application of EMI standards to electrical and electronic equipment is important and necessary to prevent possible effects caused by electromagnetic interference.

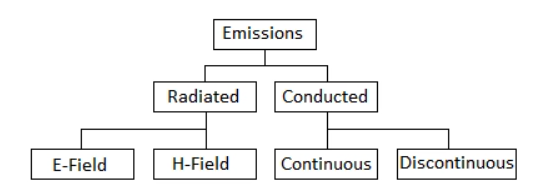

EMC Emissions are further sub-divided into two categories:

- Radiated Emissions

- Conducted Emissions

An electromagnetic field consists of the following components:

- Electric Field (E-Field) – Usually measured in volts per meter (V/M)

- Magnetic Field (H-field) – Usually measured in amps per meter (A/m)

1. Radiated Emissions

Radiated Emissions (E-Field):

Radiated emissions are electromagnetic interference (EMI) or disturbances that originate from frequencies generated internally by an electronic or electrical device. Radiated emissions can present challenging compliance issues, for some general guidance please check out our article EMC Radiated emissions common issues and solutions. Radiated emissions are propagated through the air directly from the device’s chassis or from interconnected cables such as signal ports, wired ports such as telecommunication ports or power conductors. A great example is HDMI ports and the associated EMI that can radiate from these cables, we used it as a case study, the article can be found here; EMC compliance for HDMI Radiated Emissions testing (EMI). During EMC testing, radiated emissions measurements are made using a spectrum analyzer and or an EMI receiver and a suitable measuring antenna.

Radiated Emissions (H-field):

The magnetic component of the electromagnetic wave is using a spectrum analyzer and or an EMI receiver and a suitable measuring antenna. Typical magnetic field antennas include loop antennas and also include specific antennas as per CISPR 15 such as the Van Veen Loop. The Van Veen Loop antenna is essentially three-loop antennae constructed together that measures the magnetic field emissions of a product in three-axis (X, Y and Z).

The following are some EMC standards that specify limits on radiated emissions:

- CISPR 32: This standard applies to multimedia equipment (MME) as defined as having a rated r.m.s. AC or DC supply voltage not exceeding 600 V. It establishes the requirements which provide an adequate level of protection of the radio spectrum, allowing radio services to operate as intended in the frequency range 9 kHz to 400 GHz;

- FCC 15: This standard sets limits on the amount of electromagnetic radiation allowed from digital and electronic devices such as wristwatches, musical instruments, computers, telephones, and low-power transmitters;

- FCC 18: This standard sets the limits on the emission of electromagnetic energy produced by industrial, scientific, and medical equipment (ISM);

- IEC 61000-6-3: This standard sets the electromagnetic emission limits for equipment in residential environments;

- IEC 61000-6-4: This standard sets the electromagnetic emission limits for equipment for industrial environments;

- IEC 61000-6-8: This standard sets the electromagnetic emission limits or professional equipment in commercial and light-industrial locations.

2. Conducted Emissions (Both continuous and Discontinuous):

Conducted emissions are electromagnetic interference (EMI) or disturbances that originate from frequencies generated internally by an electronic or electrical device. These emissions are then propagated along with interconnected cables such as wired ports such as telecommunication ports or power conductors. These emissions can be either continuous (continuously emits at a given frequency) or discontinuous in nature (non-constant, occurring sporadically). During EMC testing, conducted emissions measurements are made on an EMI receiver via an ISN (impedance stabilization network) located within the test chamber. For further information about conducted emissions compliance issues and EMC fixes check out our article; Conducted EMI Emissions – Typical Problems and Common Solutions.

EMC Standards for performing Conducted Emissions Testing:

- CISPR 25: This standard contains limits for the measurement of radio disturbances in onboard receivers caused by vehicles, boats, internal combustion engines, trailers, and devices in the frequency range of 150 kHz to 5 925 MHz. The limits are intended to provide protection for onboard receivers installed (per the manufacturer’s guidelines) in a vehicle from the conducted disturbances produced by components/modules in the same vehicle.

- CISPR 11: This standard specifies the limits of emissions from the equipment in the frequency range 9 kHz to 400 GHz by using a conducted measurement technique on the AC mains supply cable. The conducted emissions limits applied by this standard are intended to protect equipment connected to the same AC mains supply, and also are assumed to protect the radio communications spectrum below 30 MHz from the fields radiated by an equipment’s AC supply cables.

- IEC 61000-6-3: This is a generic standard that defines the emission test requirements for apparatus defined in the scope concerning continuous and transient, conducted, and radiated disturbances. The emission requirements have been selected to ensure that disturbances generated by apparatus operating normally in residential, commercial, and light-industrial locations do not exceed a level that could prevent other apparatus from operating as intended.

- IEC 61000-6-4: This generic standard is similar to IEC 61000-6-3. The only difference is that this standard specifies the conducted emission limits of the devices used in industrial environments.

3. Flicker test/Harmonic test:

IEC 61000-3-2

Harmonics are distortions of the normal electrical current waveform, usually transmitted by nonlinear loads such as SMPS, IGBT devices, UPS systems (and other devices whose impedance continuously varies during operation) that draw non-sinusoidal, abrupt pulses from a sinusoidal voltage source. Harmonics are integer multiples of the fundamental power frequency. If the main frequency is 60 Hz, then the 2nd harmonic will be 120 Hz, the 3rd will be 180 Hz, etc. Devices that are one of the important parts of a mains supply such as transformers, converters, etc. are prone to harmonic currents. Due to increased harmonic current, the metal wires become hot. This causes several problems such as decreased reliability, damaged insulations, short circuits, the possibility of burning of wires, smoke hazards, and even explosions at some times.

The IEC 61000-3-2 is an EMC standard by the International Electrotechnical Commission on limits for harmonic current emissions applicable to electrical and electronic equipment having an input current up to and including 16 A per phase and intended to be connected to public low-voltage distribution systems. This standard specifies the test procedures, limits, and requirements for emissions caused by the harmonic current and its components of the devices. This standard applies to the equipment to be connected to 220/380 V, 230/400 V, and 240/415 V systems operating at 50 Hz or 60 Hz. No limits have been specified for systems with nominal voltage less than 220 V (line-to-neutral).

The IEC 61000-3-2 has classified electronic and electrical equipment into four categories based on the number of pieces of equipment in use, duration of operation, power consumption, harmonics spectrum, etc. They are as follows:

- Class A: This category includes devices such as:

- Balanced three-phase equipment

- Dimmers for incandescent lamps

- Household appliances, excluding equipment identified by Class D

- Tools excluding portable tools

- Audio equipment

- Everything else excluded by Classes B, C, and D.

- Class B: This category includes devices such as:

- Portable tools

- Arc Welding system not intended for professional use

- Class C: This category includes devices such as:

- Lighting Equipment excluded by Class A

- Class D: This category includes devices with special waveforms with power levels up to 75 W and not exceeding 600 W such as:

- Personal computers and personal computer monitors

- Television receivers

IEC 61000-3-3

The IEC 61000-3-3 is an EMC standard by the International Electrotechnical Commission on the limitations of voltage fluctuations and flicker impressed on the public low-voltage system. It specifies conditions, procedures, and limits of voltage changes that may be produced by equipment under test (EUT). This standard applies to electrical and electronic equipment having an input current up to and including 16 A per phase and is intended to be connected to public low-voltage distribution systems of between 220 V and 250 V at 50 Hz line to neutral.

This standard does not apply to the equipment with reference impedance Zref of 6.4. Such equipment can be tested according to IEC 61000-3-11. Part 3-11 applies to equipment with rated input current ≤ 75 A per phase and is subject to conditional connection. Voltage fluctuations are the unwanted changes in the voltage supply from a.c. mains. Voltage flicker is the unsteadiness of a light stimulus whose luminance fluctuates with time. Varying current loads cause voltage fluctuations. If the fluctuations are large enough, they can cause an electric bulb or light to flicker with time. In addition to the unreliable output, the flickering of electric lights has adverse effects on human health. Lighting flicker causes headaches, mental strain, annoyance, migraines, and some people can suffer from epileptic seizures.

Voltage fluctuations can also cause the opening of protection circuits of a device and interrupted loss of power to the other parts of the device. Heavy load equipment like washing machines, TVs, DC generators, motors, etc. causes a fluctuation for a short time in the local voltage due to large inrush currents. This inrush current can also open fuse in the devices causing an interruption in operations.

The IEC 61000-3-3 specifies the limits on voltage variations that are generated across a reference load of a EUT based on the following factors:

- Relative maximum voltage

- Short-term flicker (Pst)

- Long-term flicker (Plt)

![[MIC] Officially issued QCVN 134:2024/BTTTT - National technical regulation on specific absorption levels for handheld and body-worn radio devices according to Circular 19/2024/TT-BTTTT of Ministry of Information and Communications](https://cdn0577.cdn4s.com/thumbs/qcvn-134_thumb_150.jpg)

![[Latest] Circular 02/2024/TT-BTTTT regulating the List of potentially unsafe products and goods under the management responsibility of the Ministry of Information and Communications](https://cdn0577.cdn4s.com/thumbs/trang-huy-hieu-the-loai-logo-2_thumb_150.jpg)